Industries

Quality Made Us Global

Automotive Interior and Exterior Components

As the number of automobile parts made from plastic has continued to grow, so have the automotive plastic injection molding projects we’ve taken on here at Global Plastics, including an array of both exterior and interior plastic components. We are IATF 16949 certified for quality service to the automotive industry.

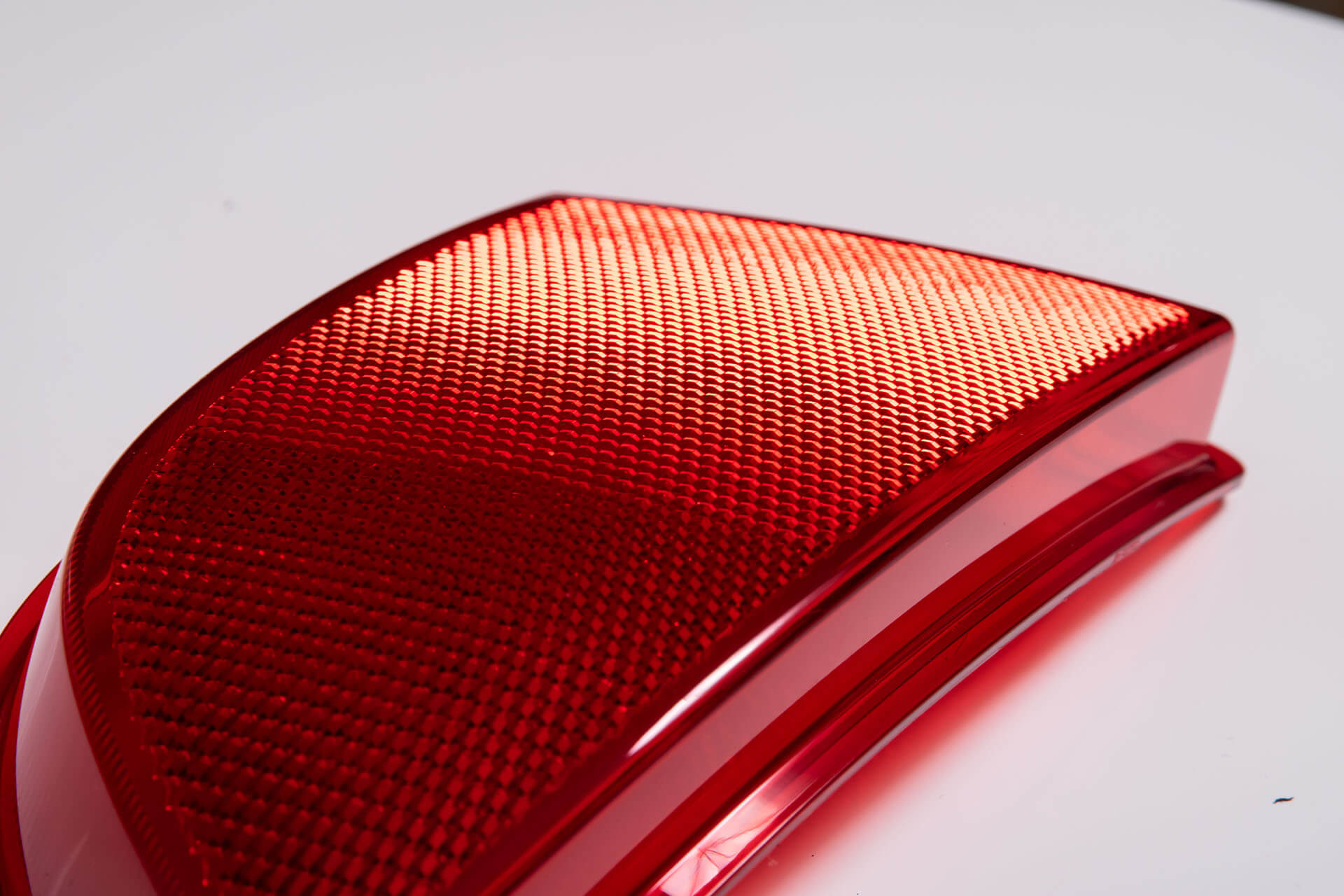

Automotive Lighting Parts

A long-established plastic injection molding niche at Global Plastics is making parts and components for automotive lighting. Whether the lenses are for traditional lamps or LED lamps, they can be created from a resin to meet your color specifications (transparent, red, and amber or yellow) and other design requirements.

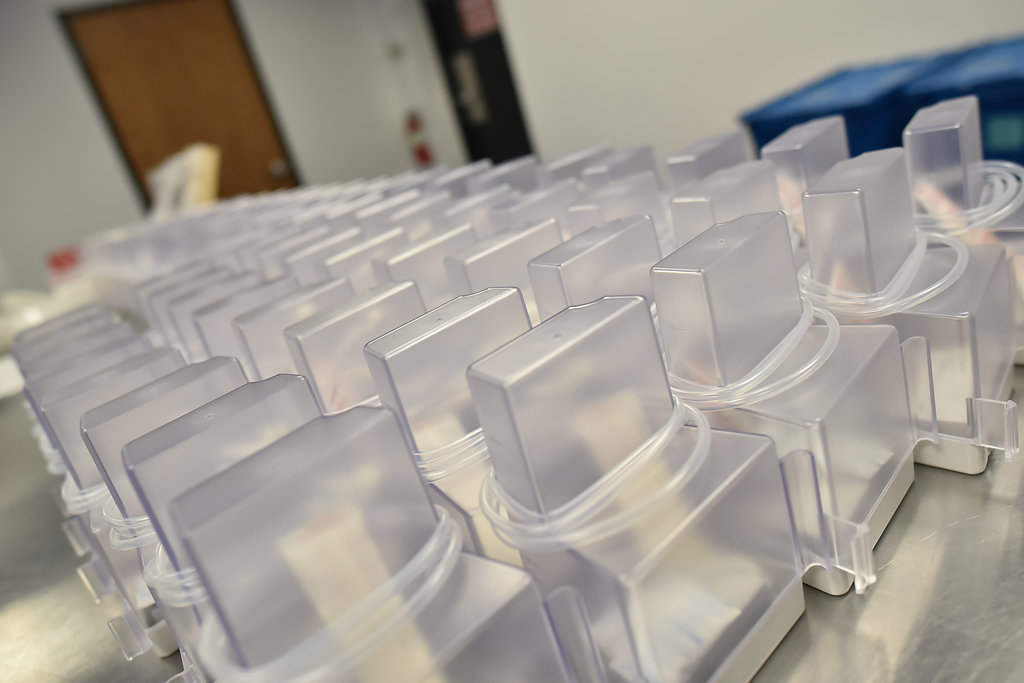

Medical Device Parts and Components

Global Plastics is ISO 13485 certified for quality management in producing plastic injection molded parts and components for medical devices, including clean room and white room requirements as needed. We’ve made test strips, catheters, biopsy needles, check valves, orthopedics, and urology pumps to name a few.

Consumer Food and Beverage

Our clients in the consumer food and beverage industry often need high-volume injection molding of plastic pieces. For one of our customers, we make over 300,000 over-caps on a daily basis. Global Plastics is SQF certified for the manufacture of food sector packaging materials and plastic molded food closures.

Custom Injection Molding

While the industries mentioned above are the most common we work with, Global Plastics has provided solutions to companies of every type to meet their plastic injection molding needs, including HVAC components, industrial gear work, electronic enclosures of all shapes and sizes, managing metal to plastic conversions, designing to combine multiple parts into one, and a host of others. No project is too small or too large for Global Plastics. Please use the contact us page of our website to start the conversation about what we can do for you.

Deep expertise + collaboration + versatility + certified for quality + committed to continuous improvement + state-of-the-art-equipment = Successful outcomes for every Global Plastics customer.