Tooling

Quality Made Us Global

Rapid Tooling When There is a Need for Speed

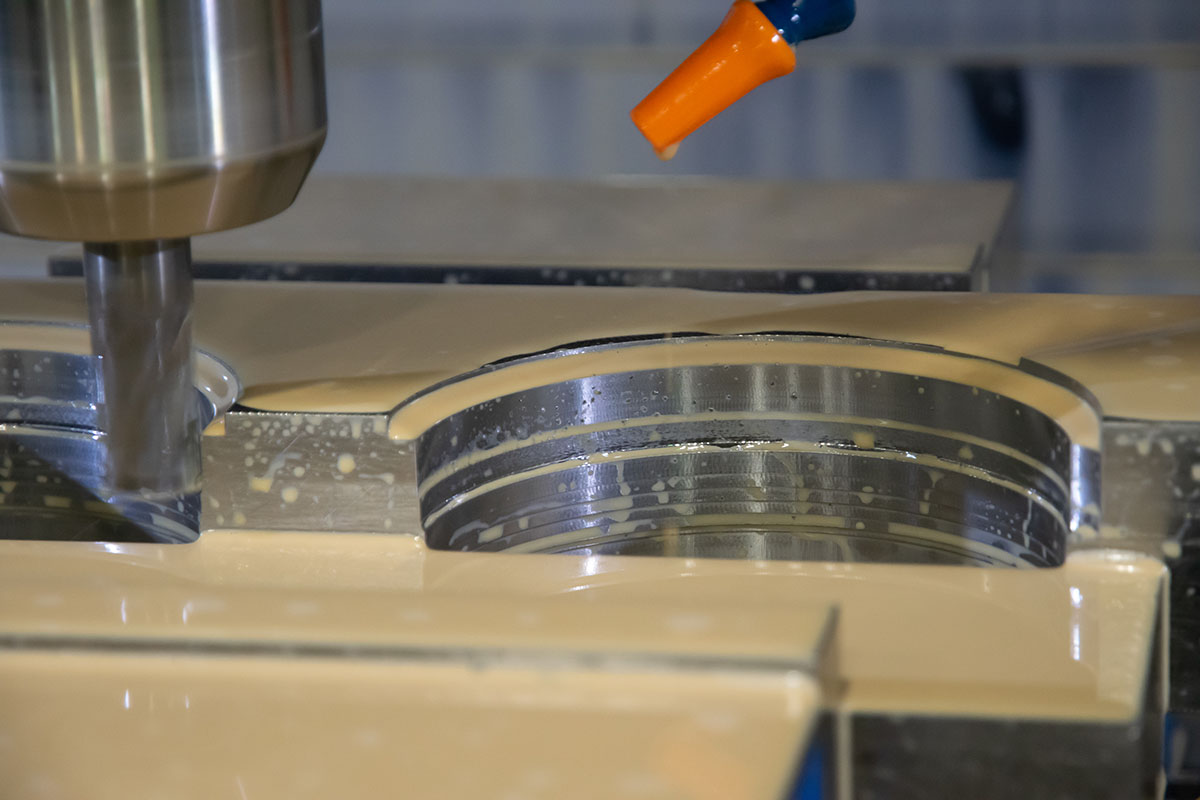

When time is tight on an initial low volume production run, rapid tooling is a good option. We can make rapid tooling molds out of aluminum or P20 Steel because it’s much faster than using hardened steel. While these rapid tooling molds are less durable than hardened steel molds, they can be created quickly for low-volume production runs of less than 100,000 parts. Soft molds are also a preferred option for rapid prototyping of molds that will eventually be tooled in hardened steel for standard high-volume production runs.

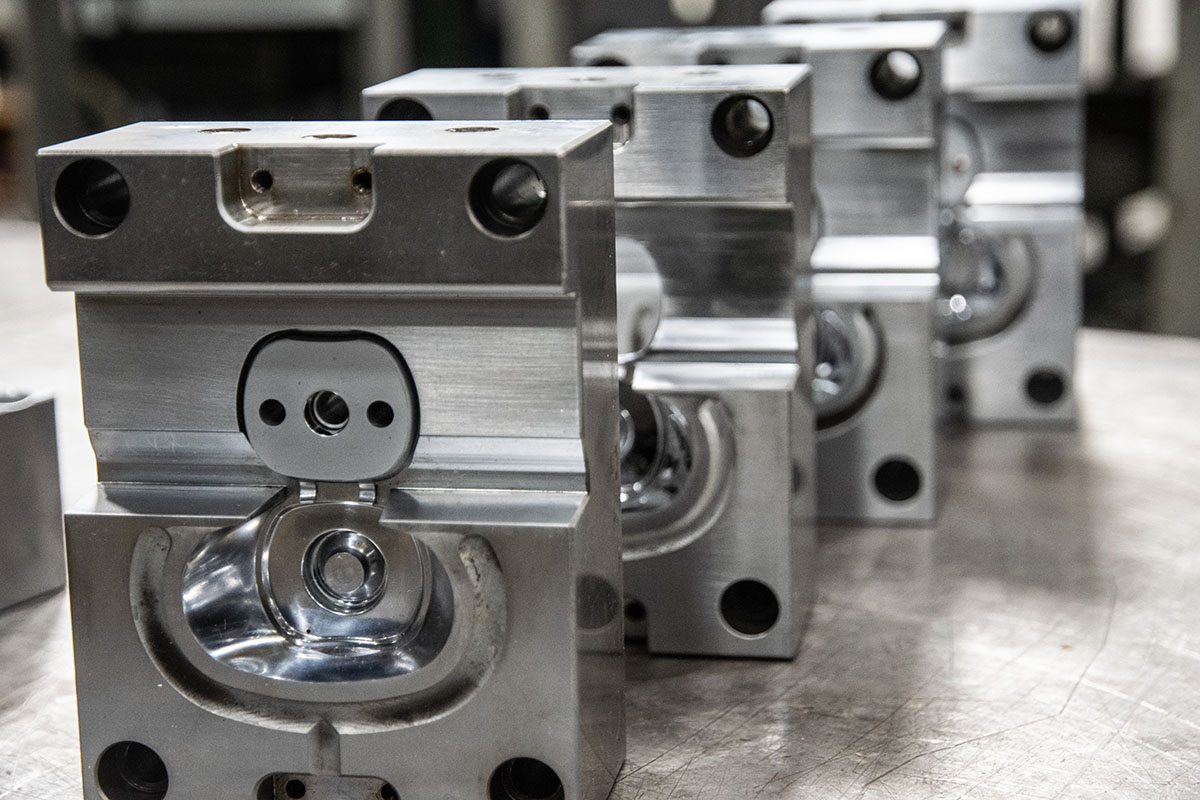

Standard Production Tooling for High Volume

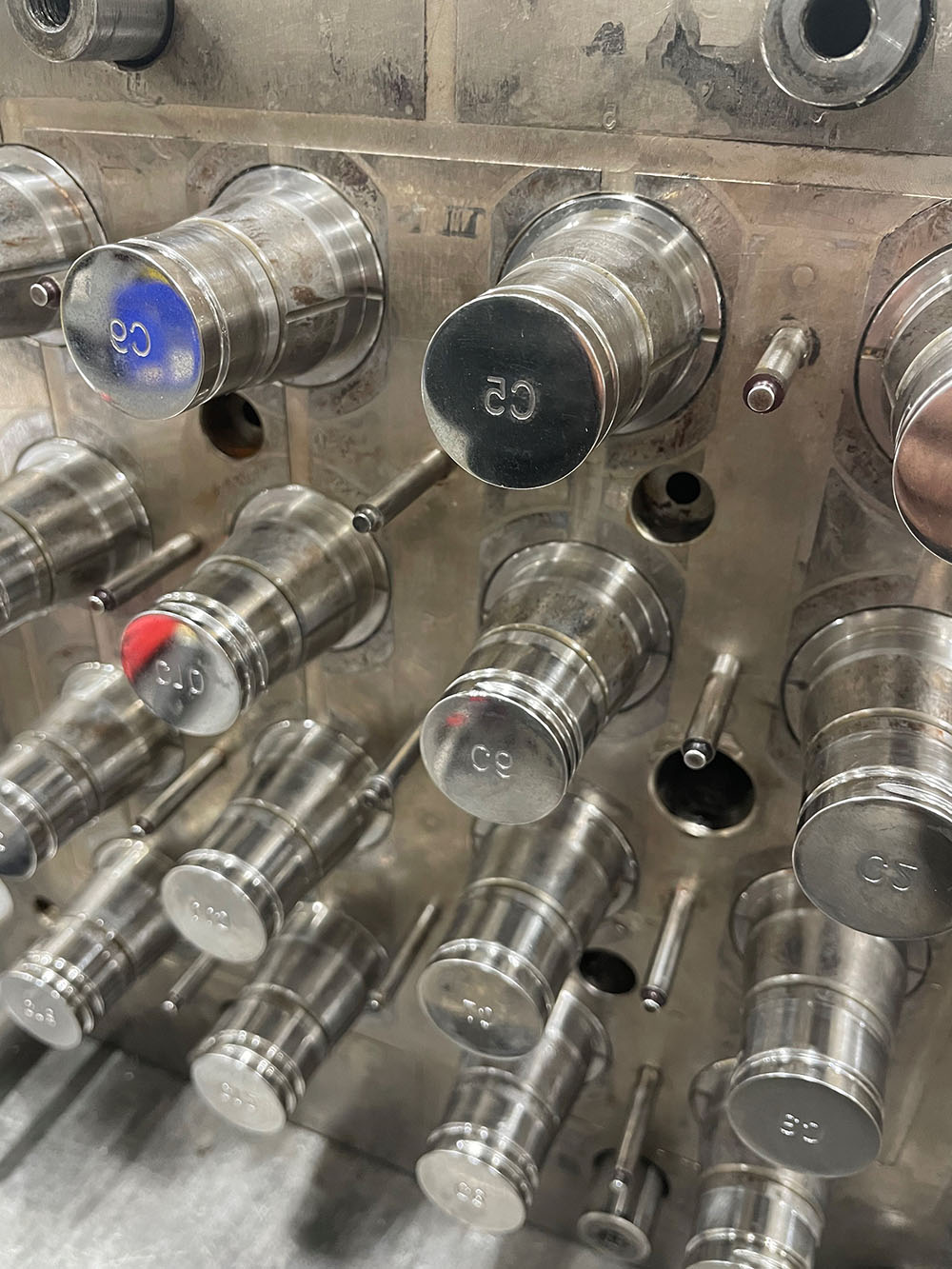

When mold design is finalized for plastic parts needed in high volumes or tight tolerances, standard production tooling is the best option. Tooling molds in hardened steel greatly increases the life of the mold. We select the type of steel for tooling that best matches the plastic part you need. Three of the most common steels for tooling high-volume production molds include the following:

- P20 Steel: A pre-hardened, low-alloy steel with good toughness at moderate strength levels commonly used in plastic injection molds.

- S7/H13 Steel: Both easy-to-tool shock resisting steel with high strength and toughness, medium wear resistance, and good deformation resistance.

- Stainless Steel: When mold corrosion is a risk from aggressive polymers such as PVC or the by-products of resin degradation during production, stainless steel is the material of choice.

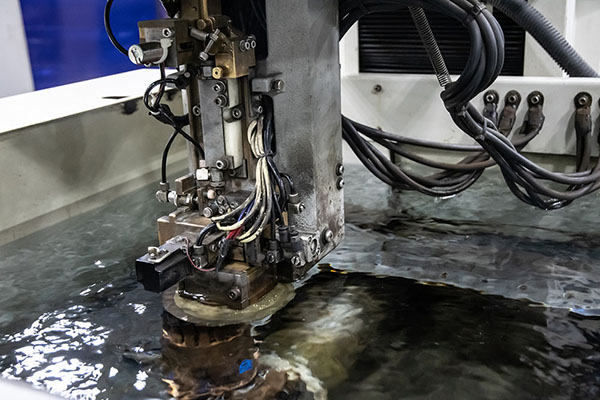

Our tooling department’s expert staff and state-of-the-art tooling facility can implement multi-cavitation, advanced gating systems, and efficient cooling to optimize the cycle time and provide shot-to-shot consistency for your plastic parts and components.

Global Plastics: Tooling Done Right to Match the Customer’s Strategy and Need

Tooling a mold, whether for prototyping, low-volume production, or high-volume production, is ultimately about quality and repeatability. At Global Plastics we take the first step in the process very seriously: Taking the time to fully understand your needs and goals for the product, part, or component you want to produce. This collaboration is essential in order for us to design the best possible mold and tooling package to meet those needs. By investing time into establishing a true partnership based on trust, each Global Plastics customer experiences better quality, fewer defects, higher throughput, and a better return on tooling investment than they’ve experienced with other vendors. We look forward to meeting you and exceeding your tooling and injection molding expectations! For more information and pricing, get the conversation started by filling out our form.