Secondary Operations

Value-Added Services for Your Success

Quality Made Us Global

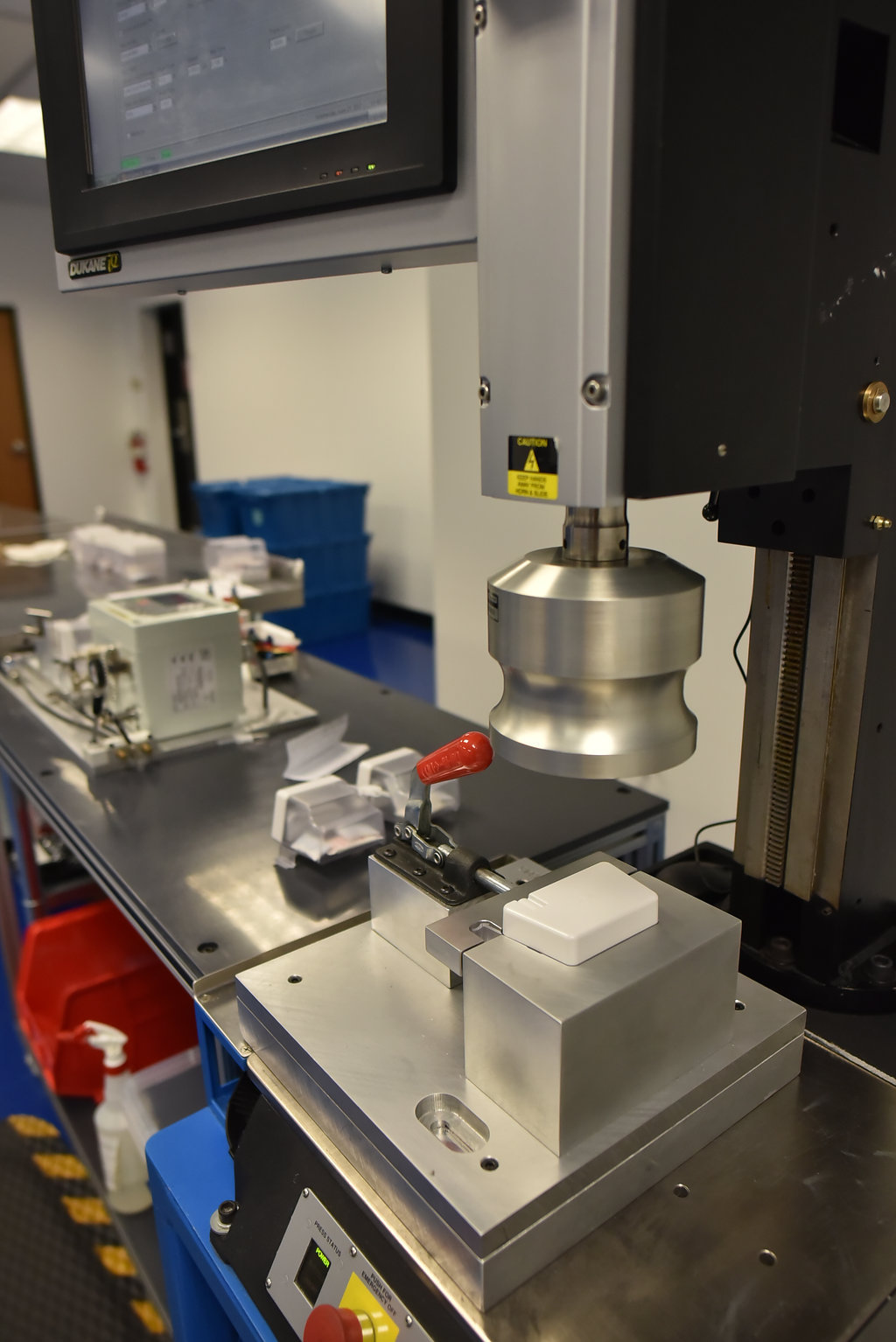

Ultrasonic Welding

Ultrasonic welding is typically faster than hot plate welding, but there are limitations. Ultrasonic welding typically isn’t suited for joining larger pieces together. The types of plastic used to create the two pieces being joined must also be a close match, both chemically and in terms of their melting points. Within these constraints, however, ultrasonic welding is a fast and cost-effective way to join plastic pieces together.

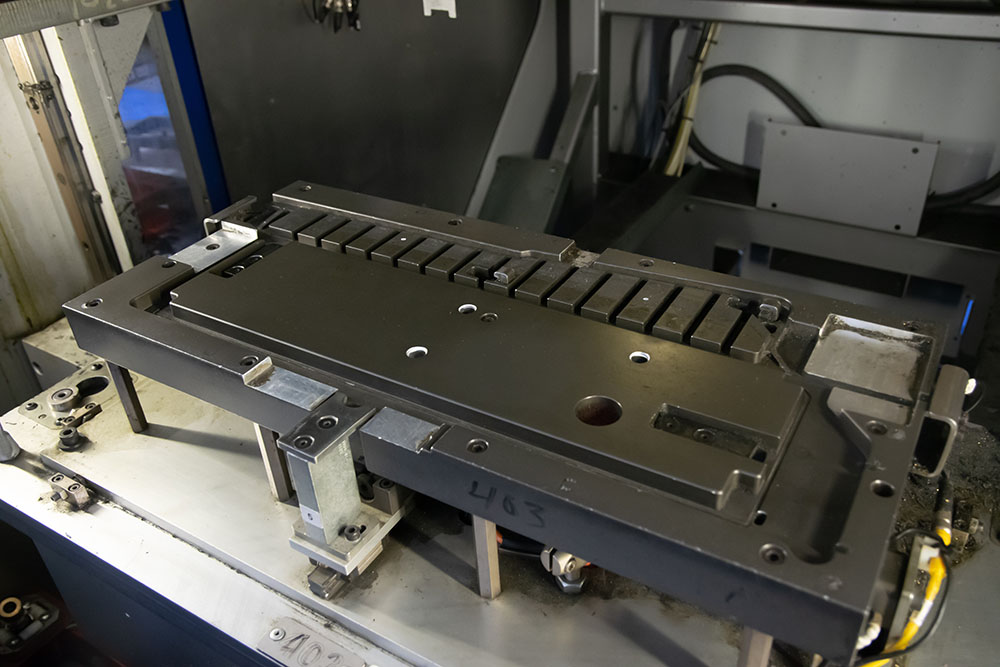

Hot Plate Welding

Hot plate welding involves a longer cool-down period than ultrasonic welding, so it’s usually not as fast, but it can be used to join much larger pieces (up to five feet in length). It can also be used to join a wider range of different thermoplastics together, as long as their melting points fall below their decomposition temperature. Hot plate welding can also handle much greater complexity of joint geometry when needed in a weld.

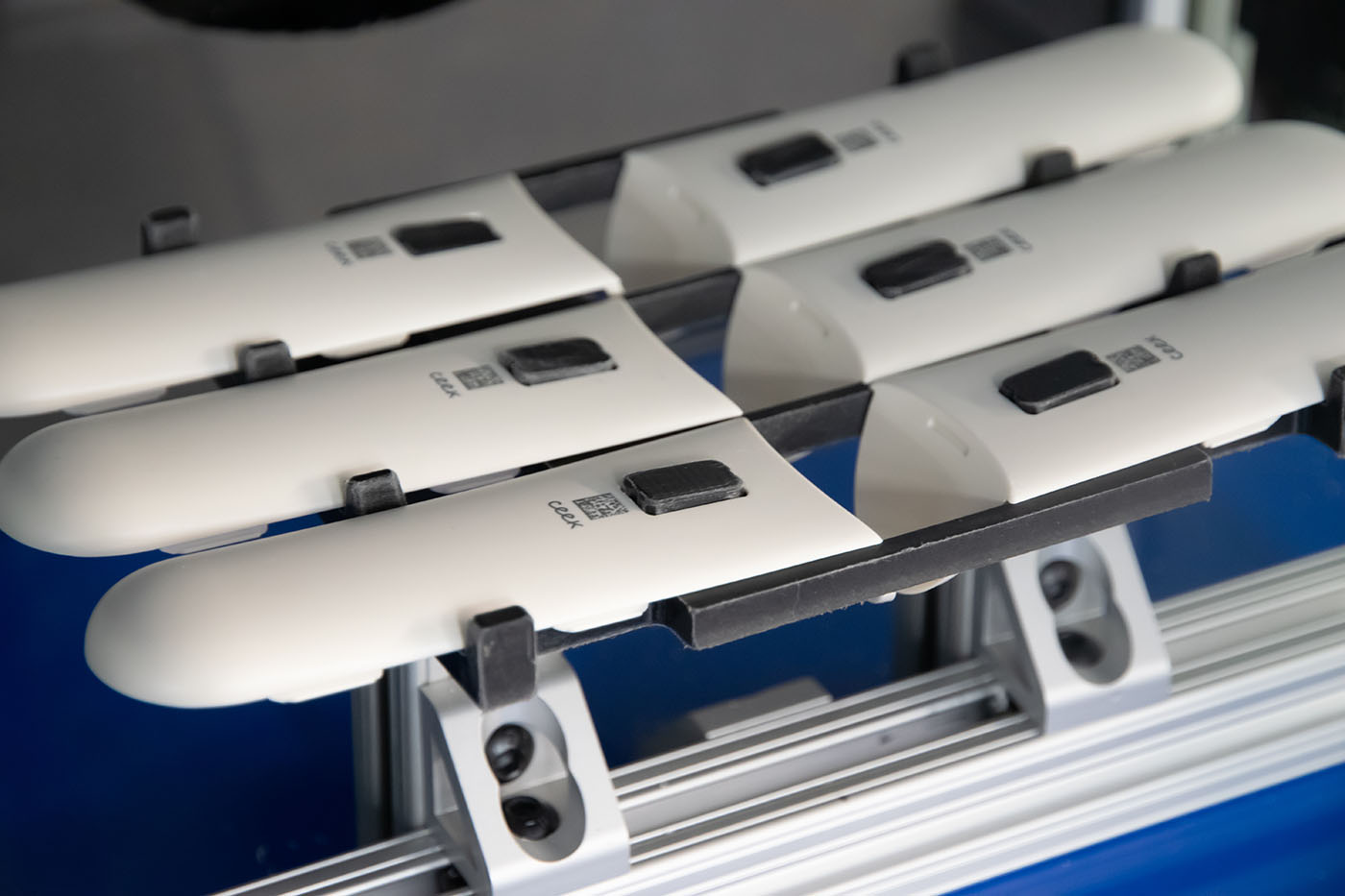

Advanced Assembly

Each new link added to your supply chain is a chance for delays or mistakes to happen. Simplifying your supply chain saves time and money. Accomplish more than just plastic injection molding and welding at Global Plastics. We offer a robust array of secondary operations and are always adding more as new needs arise. You’ll never have to ship your injection molded part off to another provider for a secondary operation like machining, drilling, assembly, decorating, or kitting because we can handle all that under one roof for you. Learn more about our secondary operations and everything else we do as a full-service plastic injection molding service provider by using the contact us page of our website to get in touch.